Conveyors are a crucial part of modern industry, helping streamline the movement of materials across various sectors. Whether you’re in manufacturing, packaging, or logistics, conveyors play a pivotal role in enhancing efficiency, reducing labor costs, and boosting overall productivity. But with so many types of conveyors available, it can be challenging to choose the right one for your specific needs. That’s where Rite Solution comes in to guide you through the diverse world of conveyor types and their uses.

What Are Conveyors?

A conveyor is a mechanical system designed to transport materials from one point to another, commonly used in industries for product handling. Conveyors come in various designs and capacities to handle different types of materials and processes.

Here is helpful information on many different conveyor types

At Rite Solution, we understand that choosing the right conveyor is essential to optimizing your production or logistics systems. Here’s a breakdown of the most common conveyor types and where they are typically used:

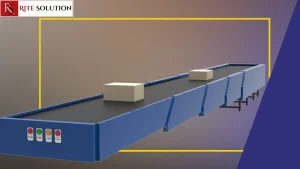

1. Telescopic conveyor

Rite Solution is one of the best manufacturers and suppliers of Telescopic Conveyor Manufacturers in India. The variety of extension lengths and belt/roller widths we offer enables the loading and unloading of bulk products of different sizes from trailers, containers, and vans. Telescopic conveyors are pivotal for industries requiring efficient loading and unloading of goods. This solution extends all the way from the permanent conveyor to the nose of the truck trailer, making the process of getting cargo in and out faster, easier and safer. We offer a wide range of telescopic conveyor systems that cater to various industrial needs. our expertise and extensive customization options, Rite Solution is the best company to call for improved speed, efficiency, safety and ergonomics at the loading dock.

2. Belt Conveyors

Use: Transporting bulk materials or items across flat or inclined surfaces.

Belt conveyors are one of the most commonly used conveyor systems in industries worldwide. They consist of a continuous loop of material, often a rubber belt, that moves items from one point to another. Belt conveyors are ideal for transporting items such as boxes, food products, or sand in bulk. They can be adjusted to move horizontally or vertically, making them highly versatile.

3. Roller Conveyors

Use: Moving items of varying sizes and weights along a production line.

Roller conveyors are designed to move items by means of rotating rollers. These conveyors are used for heavier or bulkier loads that might be difficult to move with other types of conveyors. Roller conveyors come in both powered and non-powered versions, depending on the application. Powered roller conveyors are ideal for assembly lines or warehouses, while gravity roller conveyors are useful in warehouses for sorting goods.

4. Chain Conveyors

Use: Handling heavy-duty materials in harsh environments.

Chain conveyors use a chain to transport heavy or bulky items, making them perfect for industries like automotive manufacturing, mining, or foundries. These conveyors can handle large loads and operate in tough environments where other conveyors might not work efficiently. Chain conveyors can also be used for inclined transport and are often seen in heavy-duty applications like pallet handling.

5. Screw Conveyors

Use: Moving bulk materials in a confined space.

Screw conveyors are great for handling fine, granular, or powdery materials like grains, cement, and chemicals. They use a rotating helical screw blade to move material along a trough or tube. These systems are typically used in industries such as food processing, agriculture, and manufacturing. They are especially beneficial for situations where materials need to be transported over long distances in a small footprint.

6. Pneumatic Conveyors

Use: Transporting materials through tubes using air pressure.

Pneumatic conveyors rely on air pressure or vacuum to move materials through pipes. This system is often used in the food, pharmaceutical, and chemical industries to move powders, granules, or small parts. One of the biggest advantages of pneumatic conveyors is that they can easily handle delicate or hazardous materials while maintaining a clean and safe environment.

7. Vibrating Conveyors

Use: Moving fragile or granular materials.

Vibrating conveyors utilize vibration to move materials along a trough. They are ideal for conveying granular or fragile materials, such as seeds, small food items, or minerals. They can operate in both horizontal and inclined configurations, offering flexibility in various production processes. These conveyors are also commonly found in the recycling and food industries.

8. Z-Conveyors

Use: Moving materials between different elevation levels.

Z-Conveyors are a unique type of conveyor system that uses a Z-shaped path to move items between different elevation levels. These conveyors are commonly used in packaging, distribution, and manufacturing systems where the need to lift and lower items in a compact design is essential. Z-Conveyors offer efficient solutions for vertical movement in limited spaces.

Benefits of Conveyors in Modern Industries

Incorporating the right conveyor system into your business offers numerous benefits:

- Increased Efficiency: Conveyors speed up the material handling process, reducing manual labor and downtime.

- Improved Safety: With automated material movement, the risk of workplace injuries caused by heavy lifting or repetitive motion is minimized.

- Cost-Effective: Conveyors reduce the need for manual labor, leading to long-term cost savings.

- Scalability: With a range of sizes, configurations, and customizations, conveyors can be tailored to meet your specific requirements.

Why Choose Rite Solution for Your Conveyor Needs?

At Rite Solution, we offer a comprehensive range of conveyors tailored to your needs. Our experts help you select the right conveyor type based on your materials, space, and operational goals. Whether you need a simple belt conveyor or a complex automated system, Rite Solution is your trusted partner in optimizing material handling.

Conclusion

Understanding the different conveyor types and their uses is crucial for any business looking to streamline operations. By choosing the right conveyor system, you’ll improve productivity, reduce costs, and enhance overall performance. If you’re ready to implement a conveyor system, don’t hesitate to reach out to Rite Solution. Our team is here to help you find the perfect solution for your business.

For more information, visit Rite Solution.