In today’s fast-paced industrial landscape, efficient material handling solutions are critical for businesses to optimize their workflow and enhance productivity. Telescopic conveyors have emerged as a popular choice in this regard, particularly for industries involved in loading and unloading of goods. Whether in warehouses, distribution centers, or manufacturing units, these conveyors play a pivotal role in streamlining operations.

At Rite Solution, we understand the growing need for advanced conveyor systems that cater to modern logistics requirements. One of the most common queries we receive from potential customers is about the telescopic conveyor price. In this blog, we will break down everything you need to know about the cost of telescopic conveyors, the factors influencing it, and why investing in a high-quality conveyor system can yield significant returns for your business.

What is a Telescopic Conveyor?

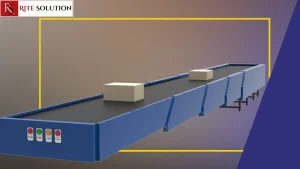

A telescopic conveyor is an extendable conveyor that can be adjusted in length to facilitate the movement of goods from one point to another. These conveyors can extend into the vehicle, enabling operators to load or unload goods more efficiently, minimizing manual effort.

Telescopic conveyors are designed to handle large volumes of goods quickly and safely, making them a preferred choice for industries that handle heavy or bulky items. Their extendable nature ensures that businesses can adjust the conveyor to their operational needs, reducing downtime and increasing productivity.

Types Of Conveyors

Conveyors are a critical part of modern industries, allowing efficient and automated material handling across various sectors, from manufacturing and logistics to retail and food processing.

Here are most common types of conveyors and their uses:

1. Telescopic Conveyor

Rite Solution has established itself as a premier Telescopic Conveyor Manufacturers in India. Our unwavering commitment to innovation and excellence has propelled us to the forefront of the industry. Telescopic conveyors are pivotal for industries requiring efficient loading and unloading of goods. This solution extends all the way from the permanent conveyor to the nose of the truck trailer, making the process of getting cargo in and out faster, easier and safer. We offer a wide range of telescopic conveyor systems that cater to various industrial needs. Our customers may select the variety of extension lengths and belt/roller widths we offer enables the loading and unloading of bulk products of different sizes from trailers, containers, and vans.

Advantages:

Adjustable length for easy loading and unloading

Reduces manual labor and handling time

Improves efficiency and safety

Disadvantages:

Higher initial cost

Requires regular maintenance

2. Belt Conveyor

Belt conveyors are the most common type of conveyor used in industries for moving materials or products from one point to another. They consist of a continuous loop of a material, usually rubber or synthetic fabric, driven by pulleys and motors.

These conveyors are suitable for moving a wide variety of materials, including grain, coal, sand, and packaged goods. They are commonly used in warehouses, assembly lines, and transportation hubs.

Advantages: Simple and versatile

Can carry heavy loads over long distances

Can operate on inclines or declines

Disadvantages:

Prone to wear and tear, requiring regular maintenance

Not suitable for extreme temperatures

3. Roller Conveyor

Roller conveyors use a series of rollers, either driven by a motor or gravity, to move items along a line. They are typically used for transporting flat-bottomed goods.

Ideal for industries such as automotive, manufacturing, and packaging, roller conveyors are used to move boxes, pallets, and other flat-bottomed items. They are also commonly found in airports for baggage handling.

Advantages:

Can handle heavy loads

Low maintenance

Simple design with customizable lengths

Disadvantages:

Limited to flat-bottomed objects

Not suitable for irregularly shaped items

4. Chain Conveyor

Chain conveyors use chains to move materials along a line. They are particularly useful in harsh environments where belt or roller conveyors might not be as effective.

Commonly used in automotive manufacturing, heavy industrial environments, and pallet handling systems. They are ideal for transporting bulk materials or heavy-duty items like pallets, barrels, and metal components.

Advantages:

Capable of handling heavy loads

Durable and long-lasting, even in harsh conditions

Suitable for high-temperature environments

Disadvantages:

Higher initial cost compared to belt conveyors

Requires regular lubrication and maintenance

5. Screw Conveyor

A screw conveyor consists of a helical screw that rotates within a tube or trough to move materials. These conveyors are typically used to move granular or powder materials.

Frequently used in industries like agriculture, food processing, and mining. They are suitable for transporting grains, cement, chemicals, and other bulk materials.

Advantages:

Efficient for moving bulk materials

Can handle both horizontal and vertical movement

Minimal space requirement

Disadvantages:

Limited to specific types of materials (bulk or granular)

Prone to wear over time, especially when handling abrasive materials

6. Pneumatic Conveyor

Pneumatic conveyors use pressurized air to move bulk materials through a pipeline. The materials are pushed or pulled through the system using air or gas pressure.

These conveyors are common in industries such as food, pharmaceuticals, and chemical processing, where cleanliness and preventing contamination is crucial. They are suitable for moving powder, pellets, or small granular materials.

Advantages:

Hygienic, making them ideal for food and pharmaceutical industries

Can transport materials over long distances, including vertically

Enclosed system prevents dust and contamination

Disadvantages:

High energy consumption

More expensive to install and maintain

7. Bucket Conveyor

Bucket conveyors, also known as bucket elevators, use buckets attached to a belt or chain to move materials vertically. These conveyors are suitable for transporting bulk materials like grains, minerals, and other free-flowing substances.

Commonly used in agricultural, mining, and construction industries. They are ideal for transporting materials to higher levels, such as grain silos or mining facilities.

Advantages:

Efficient for vertical material transport

Can handle a wide range of bulk materials

Can be enclosed to prevent spillage

Disadvantages:

Limited to bulk materials

Buckets may wear over time and require replacement

8. Slat Conveyor

Slat conveyors consist of slats or plates made from wood, steel, or other materials. These slats are connected to chains, and the system is powered by motors to move products along a set path.

Slat conveyors are often used in heavy-duty industries such as automotive manufacturing, where parts or components need to be moved through assembly lines. They are ideal for transporting heavy or irregularly shaped items.

Advantages:

Robust and durable

Can handle heavy, hot, or abrasive materials

Suitable for assembly line processes

Disadvantages:

More expensive than other conveyor types

Requires regular maintenance and inspection

9. Overhead Conveyor

Overhead conveyors use a track or rail system suspended from the ceiling, with hooks or carriers that move along the track to transport goods. These conveyors are typically used to move items through production lines or for storage purposes.

Commonly used in automotive assembly, garment manufacturing, and warehouse storage. They are ideal for transporting items above ground level, freeing up floor space for other operations.

Advantages:

Frees up floor space for other operations

Can transport items through multiple levels

Capable of handling heavy loads

Disadvantages:

More complex to install and maintain

Higher initial investment cost

10. Overhead Conveyor

Overhead conveyors use a track or rail system suspended from the ceiling, with hooks or carriers that move along the track to transport goods. These conveyors are typically used to move items through production lines or for storage purposes.

Commonly used in automotive assembly, garment manufacturing, and warehouse storage. They are ideal for transporting items above ground level, freeing up floor space for other operations.

Advantages:

Frees up floor space for other operations

Can transport items through multiple levels

Capable of handling heavy loads

Disadvantages:

More complex to install and maintain

Higher initial investment cost

Average Price Range for Telescopic Conveyors

While the price of telescopic conveyors can vary widely depending on the factors mentioned above, most models fall within a certain price range. Basic manual telescopic conveyors typically start at around $5,000 to $10,000. For more advanced automated models with higher load capacities and additional features, the price can range from $15,000 to $50,000 or more.

It’s important to note that these prices are indicative and can fluctuate based on factors such as location, supplier, and customization requirements. Businesses should obtain quotes from multiple suppliers to compare prices and ensure they are getting the best value for their investment.

Visit Our Site For Top Telescopic Conveyor Price

Investing in a telescopic conveyor is a strategic decision that can yield significant benefits for your business in terms of efficiency, safety, and cost savings. While the initial price of a telescopic conveyor may vary based on several factors, the long-term return on investment is undeniable. By streamlining material handling processes and reducing labor costs, a telescopic conveyor can help your business improve productivity and stay competitive in today’s fast-paced market.

Rite Solution manufacturer & supplier of Telescopic Conveyor in India. We are committed to providing high-quality telescopic conveyors at competitive prices. Our team is experienced and 10+years of experts can help you choose the right conveyor system based on your specific. We also provide Electric Winch Machine

Pingback: Pioneering Telescopic Conveyor System Manufacturer in India - Rite Solution